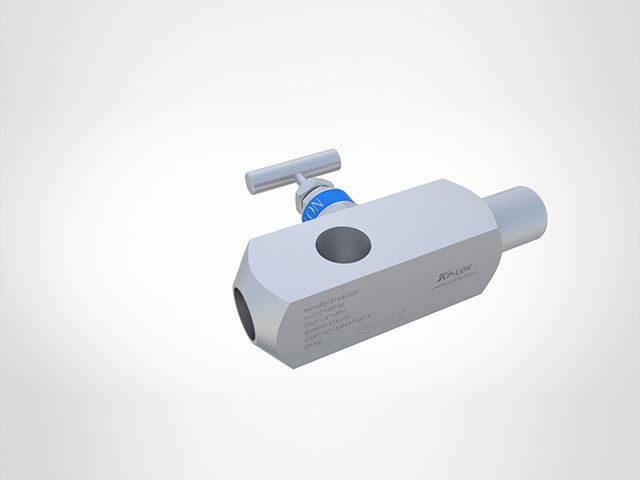

This is a type of a valve that has a port and threaded, needle-like plunger that allows smooth and accurate low of fluids .This valves operates with a narrowing pin which gradually opens a pathway for perfect fluid flow control. A spindle is used to control and adjust the fluid flow.

Like other valves, needle valves enables safe, efficient and quick operation of machines used in an industry.They have the capability to control the fluid flow rate. It is designed in a way that makes its operation easy.Needle valves have long, tapered, needle-like section at the further end of a valve stem unlike for globevalves, with a disc. The position of the plunger is control by a handwheel (small handle).lt is worth noting that,the needle valve is able to accurately regulate the a mount of fluids passing the valves through the valve’s thin-like plunger.

Needle valve can work in two instances as explained below:

The valves can either operate automatically or manually. When needle valves are operated manually, it meansthat, the handwheel is used to control the separating distance between the seat (for the valve) and the plunger. So that when the handwheel is spin in one side, the plunger is raised to enable the opening of the valves that enables the fluids to flow. On spinning the handwheel in the other side (direction), the plunger is made to move near the valve seat that minimizes the fluid flow or completely close the valves.

On the other hand, automatic needle valve operation is done in the presence of hydraulic motors or actuators.Where automated valves are joined to hydraulic motor that simply opens and shuts the valves automatically.The air actuator or the motor will change the position of the plunger with respect to the timers or even the external performance (of data collected while tracking the machinery).

The two (manual and automatic) needle valve operation provides exact fluid flow rate. The handwheel is excellently threaded, that means that it takes many turns to change plunger’s position. Hence, needle valve is an aid you to regulate the fluid flow rate in the machine.

Needle valves can be made from stainless steel, bronze, brass, or even metal alloys. It is advisable to pick a needle valve that is suitable and can work well with the service you intend to do. This will enable the needle valve to operate for a longer period without getting damaged, hence keeping the systems running safely and smoothly. You should always consider the efficiency and the durability of a valve. Needle valve possess all this characteristics and it should be the choice.

Important uses of Needle valves:

They are commonly used to prevent gauges from being destroyed by sudden pressure inrush of gases and fluid substances. They’re majorly useful for machines using less viscid substances with lower flow rate.

Needle valves also may be used with vacuum system, where accurate gas flow control is needed at a low pressure. For example when filling vacuum tubes, gas lasers and other related devices.